Product Category

- Sandstone Equipment

- Ore Dressing Equipment

- Dryer Machine

- Powder Grinding Equipment

- Mobile Crusher

- Briquette Machine

- Double-disk Friction Screw Press

- Calcium Silicate Board Machine

- Cable Recycling Machine

- Metal Crusher

- Pellet Machine

- Building Materials Equipment

- Compound Fertilizer Equipment

- Recommended products

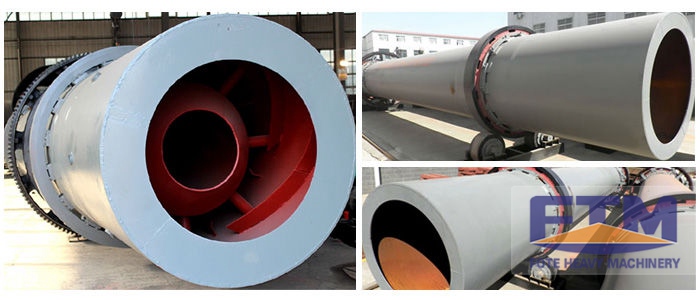

Indirect Heat Dryer

Indirect heat dryer is widely used in industries like the building materials, metallurgy, chemical engineering and cement to dry limestone slag, coal powder, slag and clay.

E-mail:market@sinoftm.com Inquiry Us Now OnlineIntroduction

Indirect heat dryer is widely used in industries like the building materials, metallurgy, chemical engineering and cement to dry limestone slag, coal powder, slag and clay. Indirect heat dryer is made up of rotary part, raising board, driving device, supporting device and seal ring, and the dryer is with reasonable structure, well-produced, high yield, low energy consumption, easy operation, etc.

Features

The indirect heat dryer has compact and simple structure and reasonable composition which increases the heat exchange rate between the materials and the heat energy and realizes good drying effect. The little basic investment reduces the one-time input. It works reliably with low energy consumption and high heat efficiency. In the mean time, it’s easy to realize automation control, reduce labor staff and save labor resource.

Parameter

| Specification (mm) | Rotating speed(r/min) | Obliquity(%) | Inlet air temperature℃ | Production capacity(t/h) | Power(KW) | Weight(t) |

| GZΦ800×800 | 3.8 | 5 | <700 | 0.8-2.0 | 5.5 | 3.5 |

| GZΦ900×10000 | 3.8 | 5 | <700 | 1.0-2.3 | 7.5 | 5.6 |

| GZΦ1200×10000 | 3 | 5 | <700 | 1.8-3.5 | 11 | 12 |

| GZΦ1500×12000 | 2.08 | 5 | <800 | 3.3-6.5 | 15 | 16.56 |

| GZΦ1500×14000 | 3.79 | 5 | <800 | 4.5-7.5 | 18.5 | 18 |

| GZΦ1800×14000 | 2.08 | 5 | <800 | 5-8 | 22 | 29 |

| GZΦ2200×12000 | 4.7 | 5 | ≤700 | 6-10 | 22 | 33 |

| GZΦ2200×16000 | 4.5 | 5 | ≤700 | 7-12 | 30 | 34.8 |

| GZΦ2400×18000 | 4 | 5 | <800 | 10-13 | 37 | 53.3 |